New Generation

Liquid Nitrogen Doser

The NovoDoser Q Series ushers in a new era of liquid nitrogen dosing, designed to meet the evolving demands of modern beverage production.

Why dosing the liquid nitrogen?

The dosing process involves supplying LN2 to the NovoDoser® through a vacuum-insulated pipe, which thenflows into the dosing head. A sensor detects the presence of the container and sends pulses to thecontroller. Upon receiving the signals, the controller instructs the dosing head to dispense the necessaryquantity of LN2 into the container.

Enhanced Container Rigidity

Improve the strength of bottles or cans to eliminate paneling issues, particularly during the hot filling process.

Container Light weighting

Decrease packaging costs and reduce the environmental carbon footprint by using lighter materials forpackaging.

Extended Product Shelf Life

By incorporating N2 gas in the product packaging, the shelf life of the product can be significantly prolonged.

Oxygen Exclusion

Improve the strength of bottles or cans to eliminate paneling issues, particularly during the hot filling process.

Nitro Infused Beverage

Decrease packaging costs and reduce the environmental carbon footprint by using lighter materials forpackaging.

Freezing

By incorporating N2 gas in the product packaging, the shelf life of the product can be significantly prolonged.

NovoDoser® Applications

Liquid nitrogen dosing solutions

Our Liquid Nitrogen Dosing Solutions revolutionize packaging by precisely injecting liquid nitrogen to enhance product integrity and extend shelf life. Ideal for various applications, it ensures optimal pressurization and freshness preservation. This technology meets modern demands for quality and sustainability, helping products stand out in the competitive market.

Bottle Rigidity

Enhance the integrity and durability of your packaged products with our precision dosing technology.

Reducing Oxidation

This innovative approach your products significantly reducing oxidation and extending shelf life without the need for artificial preservatives

Dipped Ice Cream

Liquid Nitrogen Dosing rapidly freezes dipped ice cream, locking in flavor and texture instantly. It provides an efficient, high-quality freezing method that enhances the overall sensory experience of ice cream.

Nitro Beer

Elevate your craft beer and coffee with our Nitrogen Doser. Smooth, creamy, and perfectly carbonated beverages anytime, anywhere. Revolutionize your offerings and captivate customers with every sip

A New Beer Experience: The Unique Appeal of Nitrogen-Infused Brews

Ergonomic Features And Benefits

Frost-free Nozzle

Self-generating GN2 for dosing head blanketing

Consistent Container Pressure

Deliver accurate dosing ± 1%

Lowest LN2 Consumption

Discrete dosing, for speed up to 2500* containers per minute

Lowest LN2 Losses

Proprietary vacuum insulation

with lowest heat leak 0.1 LPH

Minimized Product Splash

Lowest dose pressure in its class,0.3 psi

Sub-cooled LN2

Ensuring constant LN2 density for accurate dosing

Corrosion Resistant

Optional 316L material grade of

construction for Doser body

Lowest Maintenance

Ultra long life cycle dosing valve > 60 million; and better than IP65 rated sensors & electrical cables

Upcoming Event

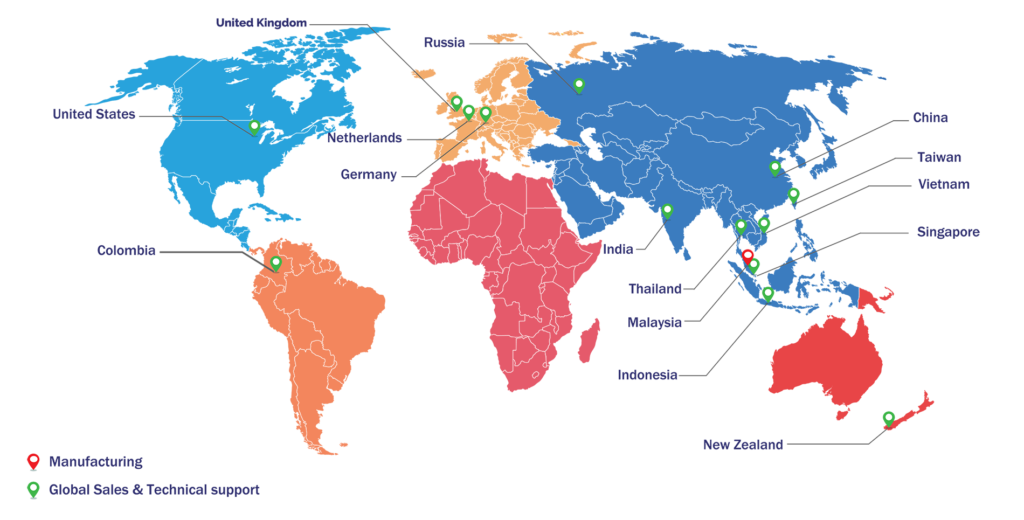

GLOBAL NETWORK

Worldwide Sale & Support

Contact

Cryogenic Specialty Manufacturing Sdn.,Bhd

No 10, Jalan PPU 3A, 47150 Puchong,

Selangor, Malaysia

Tel: +603 8051 0982

Email: [email protected]